Portfolio

A selection of engineering projects and builds, highlighting hands-on work, design, and problem-solving across manufacturing, automation, and prototyping.

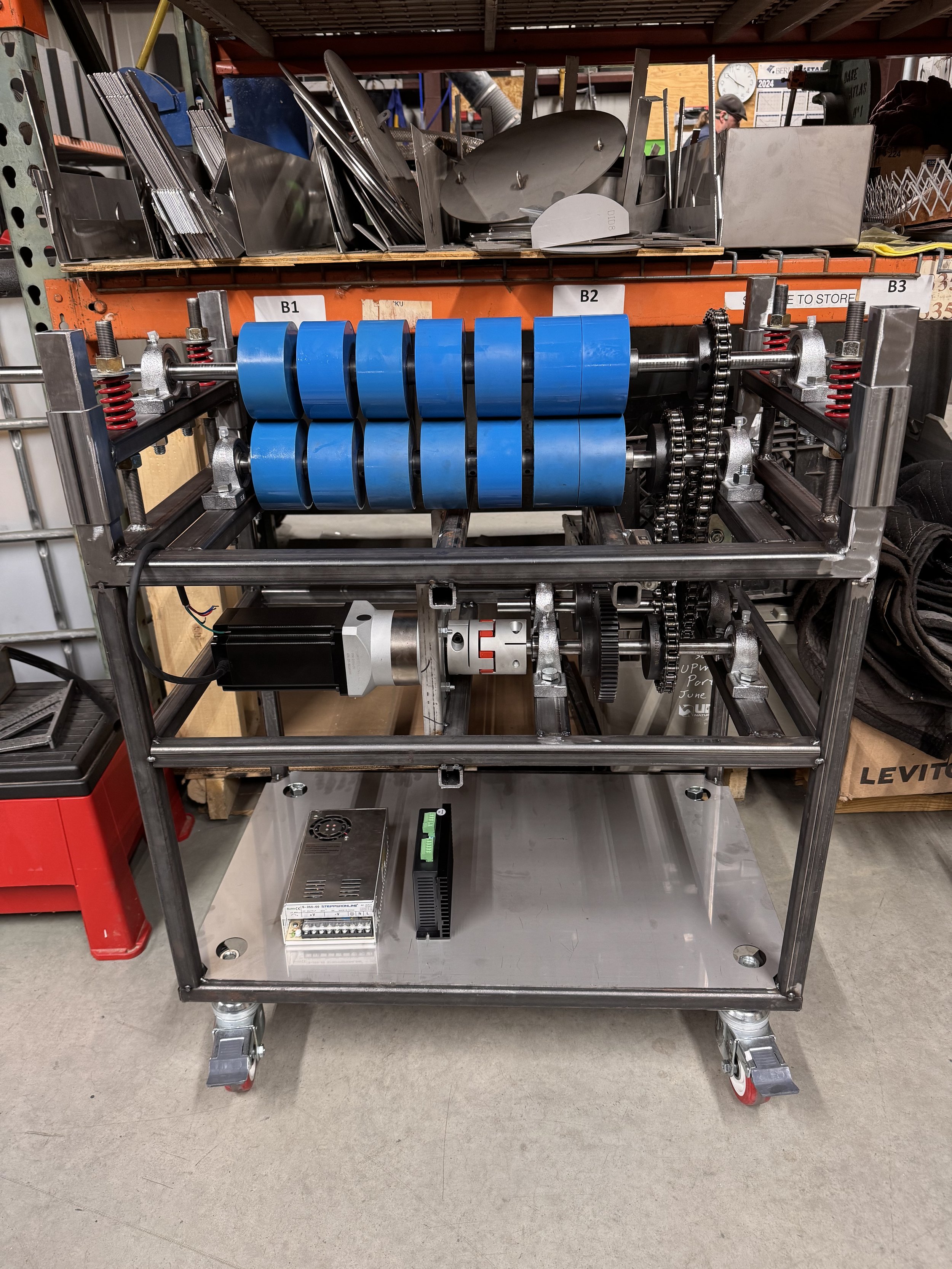

Automated Mesh Shear System

Problem

Manual shearing of expanded stainless mesh was a production bottleneck that caused injuries, fatigue, and inconsistent quality.

Solution

Designed and built a custom automation system using stepper-driven uncoilers, Raspberry Pi control, and dynamic Excel list integration to allow operators to cut precise lengths easily and safely.

Impact

Eliminated a full-time manual task, enhanced worker safety, and increased product consistency.

Skill Development

Rapid Prototyping

CAD Design

Python Scripting (GUI, threading, controls)

Welding

Fabrication

Testing

Fusion 360 API Design Package

Problem

Managing the design and CNC pipeline required four separate programs, slowing down workflow, increasing errors, and requiring high technical skill to operate.

Solution

Transitioned all design and CNC work into Fusion 360, developing a custom automation package using Fusion’s API with Python and an object-oriented approach. Automated the creation of custom sheet metal assemblies, improved CNC nesting efficiency, and integrated a custom post processor to optimize CNC laser cutting.

Impact

Reduced design time by ~90%, increased material utilization, enabled more complex part designs, and significantly lowered the technical barrier for new users — allowing faster onboarding and scaling of production.

Skill Development

High level CAD/CAM design

Python OOP approach

Product Refinement

Sheet Metal Design

Shop Manual Documentation

Problem

The existing in-house parts manual was outdated, inconsistent, and difficult for new employees to use for manufacturing and training.

Solution

Completely rebuilt the parts manual with updated manufacturing techniques, modernized visuals, standardized documentation, and broader usability across the company.

Impact

Improved manufacturing consistency, streamlined onboarding and training processes, and created a sustainable resource for managing over 100 custom parts.

Skill Development

Technical Writing

Process Standardization

Manufacturing Documentation

Visual Communication

Verbal Communication

Parts & Process Knowledge

Product Development

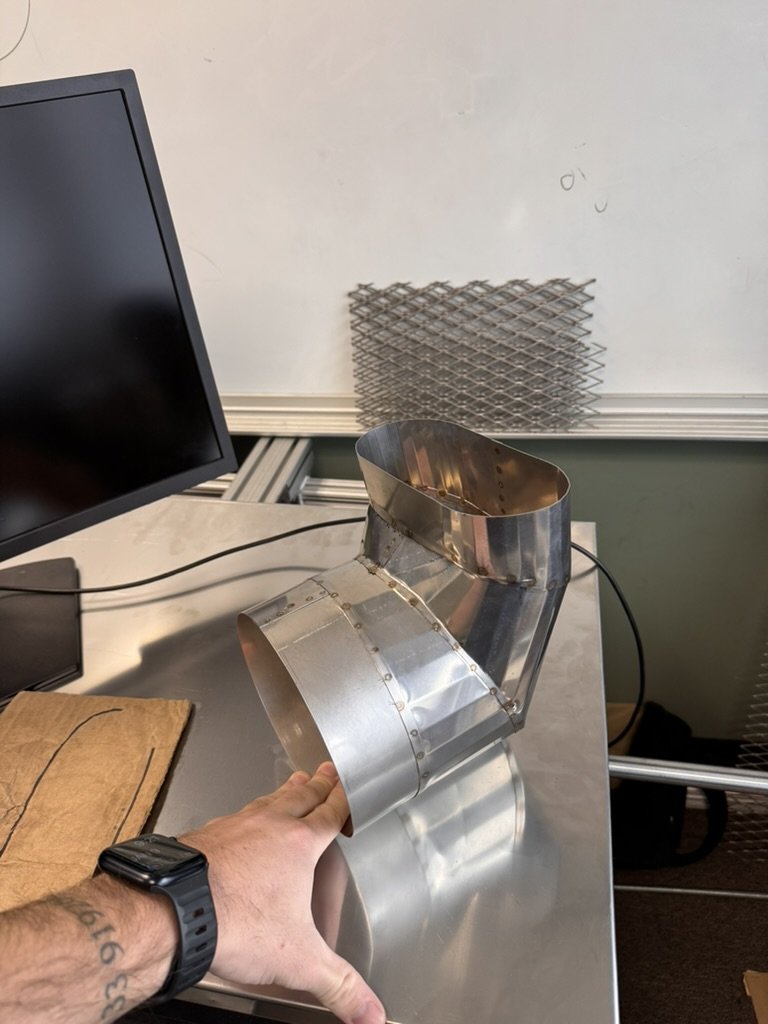

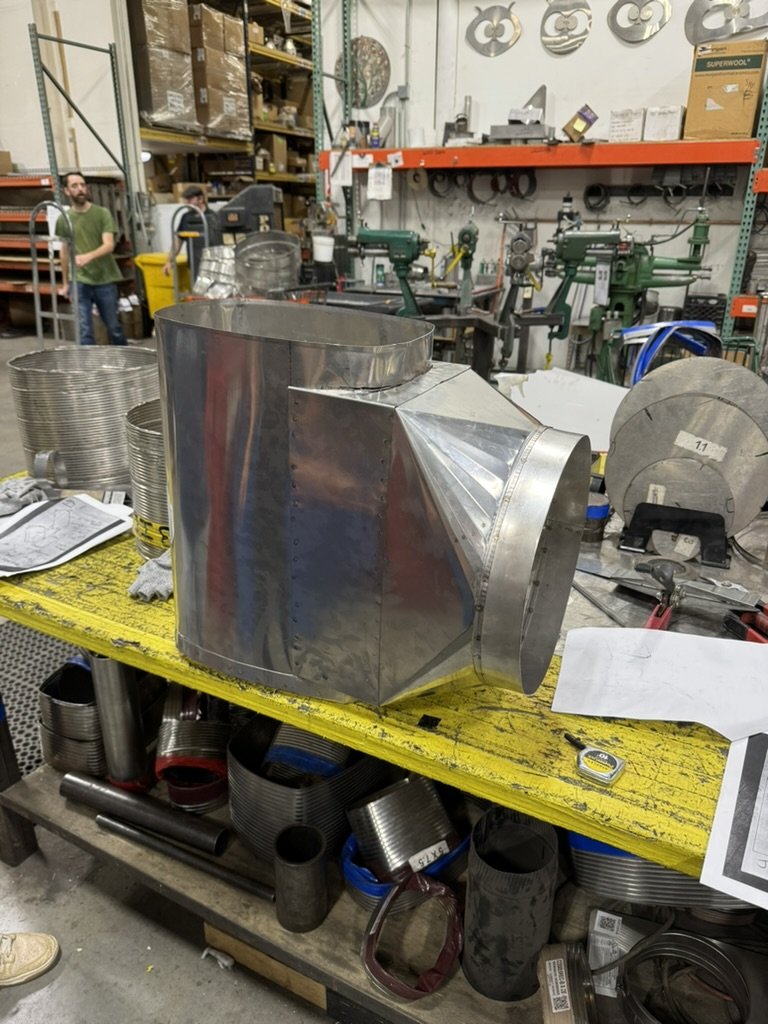

Damper Combo Cap

Problem

Development of a new product had stalled due to manufacturing challenges with existing tooling and part sourcing constraints.

Solution

Redesigned the product for manufacturability using in-house capabilities and available parts. Created new manufacturing documentation and customer reference guides, and collaborated with marketing, consultants, and field technicians to refine the design and production process.

Impact

Successfully brought the product to market, expanding the company’s product line and creating a scalable, repeatable manufacturing process that integrated customer feedback.

Skill Development

Product Development

DFM

Cross-Functional Collaboration

Technical Documentation

Additional Design

&

Work Gallery